Galvanized square steel has become an essential material in modern construction and industrial applications due to its exceptional durability and versatility. This material is widely used across various industries because of its corrosion-resistant properties and strength. Understanding the benefits, manufacturing process, and applications of galvanized square steel can help professionals make informed decisions for their projects.

In today's rapidly evolving construction and manufacturing sectors, choosing the right materials is crucial. Galvanized square steel stands out as a preferred option because of its ability to withstand harsh environmental conditions while maintaining structural integrity. This article will explore the key features, advantages, and practical uses of this versatile material.

Whether you're a contractor, engineer, or someone interested in learning more about industrial materials, this guide will provide valuable insights into why galvanized square steel is a top choice for many professionals. Let's dive deeper into the world of galvanized square steel and discover what makes it a game-changer in the industry.

Read also:Hawk Tuah Red Bull Energy Drink A Comprehensive Guide To The Energizing Beverage

What is Galvanized Square Steel?

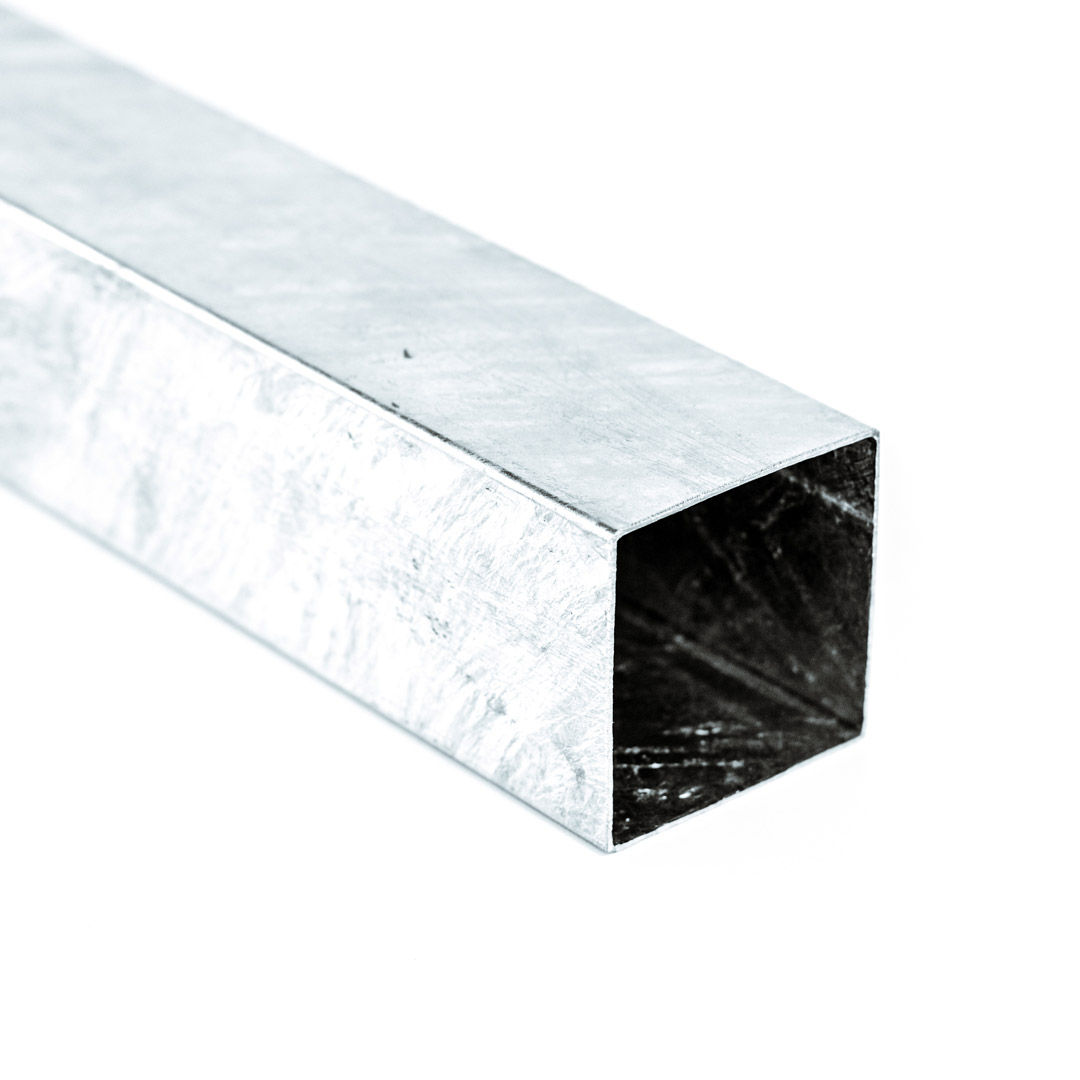

Galvanized square steel refers to square-shaped steel bars that have undergone a galvanization process to enhance their corrosion resistance. The galvanization process involves coating the steel with a layer of zinc, which creates a protective barrier against rust and environmental damage. This makes galvanized square steel an ideal choice for both indoor and outdoor applications.

One of the primary reasons for its popularity is the combination of strength and durability. The square shape ensures stability and uniformity, making it suitable for structural frameworks, fencing, and various engineering projects. Additionally, the galvanized coating extends the lifespan of the steel, reducing maintenance costs and increasing its value over time.

Manufacturing Process of Galvanized Square Steel

Steps in Galvanization

The manufacturing process of galvanized square steel involves several critical steps to ensure its quality and performance:

- Cleaning: The steel is thoroughly cleaned to remove any dirt, grease, or impurities that could interfere with the galvanization process.

- Fluxing: A flux solution is applied to the steel to enhance the adhesion of the zinc coating.

- Hot-Dip Galvanizing: The steel is submerged in a bath of molten zinc at high temperatures, allowing the zinc to bond with the steel's surface.

- Cooling and Inspection: After the galvanization process, the steel is cooled and inspected to ensure it meets industry standards.

This meticulous process ensures that the galvanized square steel is both durable and reliable, making it a preferred choice for demanding applications.

Benefits of Using Galvanized Square Steel

Key Advantages

Galvanized square steel offers numerous benefits that make it an attractive option for various industries:

- Corrosion Resistance: The zinc coating provides a robust barrier against rust, extending the lifespan of the steel.

- Strength and Stability: The square shape ensures structural integrity, making it ideal for load-bearing applications.

- Cost-Effective: Its durability reduces maintenance and replacement costs, offering long-term savings.

- Environmental Resistance: Galvanized square steel can withstand harsh weather conditions, making it suitable for outdoor use.

These advantages make galvanized square steel a practical choice for construction, automotive, and manufacturing industries.

Read also:Baby Alien Leak The Controversial Phenomenon Unveiled

Applications of Galvanized Square Steel

Industries and Uses

Galvanized square steel finds applications in a wide range of industries due to its versatility and performance:

- Construction: Used in structural frameworks, scaffolding, and fencing.

- Automotive: Ideal for vehicle components that require high strength and corrosion resistance.

- Manufacturing: Employed in machinery parts, tools, and equipment.

- Agriculture: Utilized in farm equipment, gates, and livestock enclosures.

Its adaptability to different environments and conditions makes it a versatile material for diverse projects.

Comparing Galvanized Square Steel with Other Materials

Why Choose Galvanized Square Steel?

When compared to other materials, galvanized square steel offers distinct advantages:

- Steel vs. Aluminum: While aluminum is lighter, galvanized steel provides superior strength and cost-effectiveness.

- Galvanized vs. Ungalvanized Steel: The zinc coating significantly improves the corrosion resistance of galvanized steel.

- Square vs. Round Steel: The square shape offers better stability and alignment in structural applications.

These comparisons highlight the unique qualities of galvanized square steel, making it a preferred choice for many professionals.

Market Trends and Demand for Galvanized Square Steel

Global Growth and Opportunities

The demand for galvanized square steel is on the rise globally due to increasing infrastructure development and industrial growth. According to a report by Allied Market Research, the global galvanized steel market is expected to grow at a CAGR of 4.5% from 2021 to 2028. This growth is driven by factors such as urbanization, technological advancements, and the need for durable materials in construction.

Key players in the market are focusing on innovation and expanding their production capacities to meet the growing demand. This presents opportunities for businesses to invest in high-quality galvanized square steel products.

Environmental Impact and Sustainability

Green Building Solutions

Galvanized square steel contributes to sustainable construction practices by offering long-lasting solutions that reduce the need for frequent replacements. The zinc coating is recyclable, and the steel itself can be reused, minimizing waste and environmental impact.

As industries increasingly prioritize eco-friendly materials, galvanized square steel aligns with green building standards and regulations. Its durability and recyclability make it a responsible choice for environmentally conscious projects.

Cost Considerations and Maintenance

Investing in Long-Term Value

While the initial cost of galvanized square steel may be higher than untreated steel, its long-term benefits outweigh the expenses. The reduced maintenance requirements and extended lifespan make it a cost-effective option for both short-term and long-term projects.

Regular inspections and minor touch-ups can further enhance its durability, ensuring it remains in optimal condition for years to come.

Challenges and Solutions in Galvanized Square Steel Usage

Overcoming Limitations

Despite its many advantages, galvanized square steel does have some limitations. For instance, the zinc coating can be damaged if exposed to certain chemicals or extreme temperatures. However, these issues can be mitigated through proper handling and maintenance practices.

Coating thickness and quality control during the manufacturing process also play crucial roles in ensuring the steel's performance. Working with reputable suppliers and following industry guidelines can help overcome these challenges.

Future Innovations in Galvanized Square Steel

Advancements in Technology

As technology continues to evolve, innovations in the galvanization process and steel production are expected to enhance the performance of galvanized square steel. Research into advanced coatings and alloy compositions aims to improve its resistance to corrosion and increase its versatility.

These advancements will further solidify galvanized square steel's position as a leading material in the construction and manufacturing industries.

Conclusion

Galvanized square steel has proven to be an invaluable material in modern construction and industrial applications. Its exceptional durability, versatility, and cost-effectiveness make it a top choice for professionals across various sectors. By understanding its manufacturing process, benefits, and applications, you can make informed decisions for your projects.

We invite you to share your thoughts and experiences with galvanized square steel in the comments section below. Additionally, feel free to explore other informative articles on our website to stay updated on the latest trends and innovations in the industry. Together, let's build a brighter and more sustainable future with high-quality materials like galvanized square steel.

Table of Contents

- What is Galvanized Square Steel?

- Manufacturing Process of Galvanized Square Steel

- Benefits of Using Galvanized Square Steel

- Applications of Galvanized Square Steel

- Comparing Galvanized Square Steel with Other Materials

- Market Trends and Demand for Galvanized Square Steel

- Environmental Impact and Sustainability

- Cost Considerations and Maintenance

- Challenges and Solutions in Galvanized Square Steel Usage

- Future Innovations in Galvanized Square Steel

- Conclusion

.png)